Dot peening is a permanent automated process for labeling heavy duty machinery, parts, and equipment. It is a process that ensures reliable traceability for locating parts, machinery, and tools. Its clarity and precision guarantee high quality labeling and marking that are completed efficiently, accurately, and effortlessly. Read More…

Moller North America is committed to customer satisfaction. Our line of products ranges from bagging, conveying, palletizing, to stretch-hooding, stretchwrapping and shrinkwrapping a variety of products. Contact us today to for all of your packing, palletizing, and protection needs.

American-Newlong is the world's leading manufacturer of automated, open-mouth bag packaging and closing systems and equipment. We offer a wide range of filled bag sewing machines, automatic bag heat sealers, robotic bag palletizers, bag making machines and semi-automated and automated bag packaging equipment that weigh, pack, close, check weigh, distribute, and palletize.

Trust Frain Industries for all your packaging equipment! We offer a variety of packaging equipment including stretch wrapper machines, filling machines, wrappers, shrink wrap machines, and more! We guarantee that all Frain machines will work for you so that you can work less!

TopTier is the preferred vendor for over 800 consumer packaged goods manufacturers with sales throughout North America and select countries worldwide. TopTier manufactures palletizers exclusively and serves both Fortune 1000 and mid-size companies. Contact us today for more information!

Packsize designs inventive packaging machinery that reduces unnecessary packaging material and promotes sustainable packaging solutions through on-demand packaging. We design integrated, automated packaging machines that create and pack boxes in the moment - only using the packaging material needed. We design systems in a variety of sizes, speeds, and capabilities. Our customers trust our...

More Dot Peening Manufacturers

The reliability of the process eliminates the need for scrapping, relabeling, and reworking of products due to improper identification. Once the letters, numbers, or identifying marks are peened, it is impossible to remove them.

What is Dot Peening?

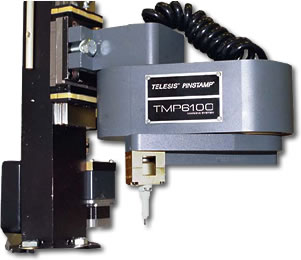

The process of dot peening uses a pneumatically driven pin that punctures or peens the surface of an item with very small closely spaced dot indentions to form letters, numbers, lines, or images. The images produced are exceptionally clear and impossible to remove by conventional means such as cleaners, solvents, or weathering.

Dot peening is a rapid marking, labor saving, process that places programmed numbers, letters, words, images, or other identifying marks on materials, equipment, or products. Once the data is input, the machine does the rest, accurately, effortlessly, and precisely using minimal force.

Types of Dot Peening Machines

There are several types of dot peening machines that can be adapted to any type of production or inventory control system. Available methods can be adjusted to fit unusual and unique conditions depending on the need and types of markings.

Dot peening machines have a touchscreen, or keypad, for entering the data to be engraved. The control panel offers the operator a variety of choices for data to be input such as words, letters, and X and Y axes. Benchtop machines come with an adjustable tool stand and base to hold the mechanism. The marking device can be raised and lowered to accommodate any size of equipment or part.

Portable machines offer the ability to mark heavy duty equipment such as presses, extrusion equipment, and cauldrons. The mechanism is set on a pistol grip handle that has a trigger to activate the marking pin. A controller, not on the portable marker, is where the data is downloaded into the handheld device. The operator places the cradle of the device on the piece to be marked and pulls the trigger.

Sophisticated dot peening machines are Integrated into production and assembly operations. The programmability, marking, and peening are included as part of product completion. These types of devices enhance and simplify the production process as well as eliminate the need for hand or manual labeling.

Benefits of Dot Peening

Aside from the obvious benefit of placing permanent identification on inventory, there are several other factors that make dot peening one of the easiest and most convenient methods for inventory control. The process is exceptionally low stress since errors in data entry can easily be corrected during the programming process.

The permanent marks that are placed on equipment and materials are minimally invasive causing limited damage or distortion. The depth and size of the pin impressions are adjustable to meet the needs of the material being marked.

The control and location of inventory is a central aspect of supply chain management and movement. The process of dot peening is a permanent and lasting method for identifying, locating, and finding vital tools and equipment.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services